Who We Are

royalstar.tr

Royalstar is the distributor of Deif in Turkey. It provides sales, technical support and project design of Deif products. Royalstar , is dedicated in providing integrated solutions such in power control solution of the following field: land, marine ,solar, hydro, wind , ESS, for diesel ,Gas, biogas ,hydro, solar system and gas turbine plant , IPP power plants, micro grid .

We have extensive experience to support our client and partner with DEIF solution as official dealer in TURKEY AND IRAQ

Services

Some of Our Professional Works..

Marine Control Systems

Royalstar offer high quality marine solution for yacht and ship, with deif synchronizations’ system include power management, plus hybridization with ESS by new product PPM300, AC and DC bus-bar.

Diesel Generator Synchronization

Royalstar Energy Systems has carried out various projects regarding the synchronization of multi diesel generators with multi grid with soft transfer without interrupted also integrated with PV ,ESS ( solar , emergency storage system) data center applications with redundant ( hot standby ) with secure high quality power management

Read More »

Solar Hybrid Solution (Micro Grid)

Deif solar controller get maximum benefits for hybrid Micro Grid , with full power management of all parties (Grid , Diesel Generator , PVsystem , ESS ) to insure start/ stop of generator with min. load on generators, save fuel , prevent PV system stop when grid off, also make zero export to main peaking....

Read More »

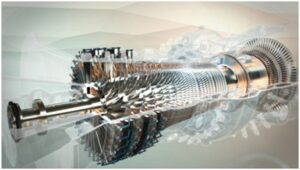

Gas Turbine Control and Instruments

In general, Royalstar supplying a complete package of their gas turbine generator including all field instruments, fire & gas detectors, and a dedicated PLC for the GTG control & safety system.

Read More »Projects

Some of our projects..

Royalstar News and Announcement

Follow for industry news and innovations..

By

royalstar.trHow much electricity does a solar panel produce?

The amount of electricity a solar panel produces depends on three important factors: the size of the panel, the efficiency of the solar cells inside, and the amount of sunlight the panel gets.

Tipik bir güneş panelinden neler bekleyebileceğinizi ve bu güç çıkışının evinizde kullandığınız alet ve cihazlar için ihtiyaç duyduğunuz güçle nasıl karşılaştırıldığını açıklayacağız.

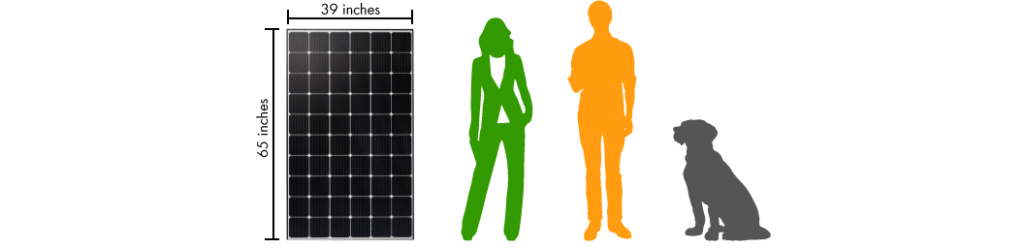

How big are solar panels?

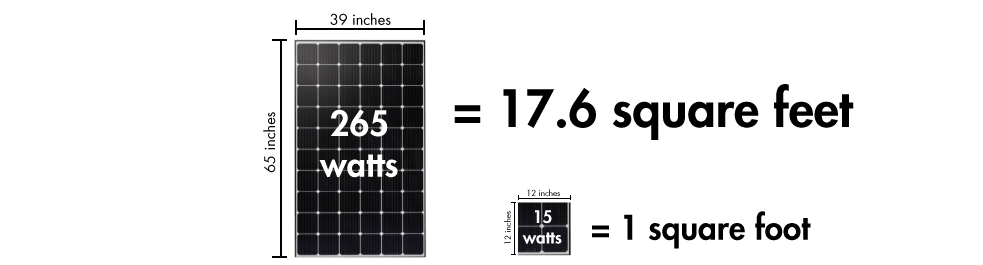

When we say “solar panel,” what we’re talking about is a typical silicon photovoltaic panel for residential use. These days, most solar panels are about 5 and a half feet tall and a little more than 3 feet wide:

If you look closely at the solar panel in the image above, you’ll notice 60 little squares. These squares are actually individual solar “cells,” which are linked together by wires. The cells are where electricity is made, and the wires carry the electricity to a junction box where the panel is hooked into a larger array.

Why does solar panel size matter?

The more solar cells working in tandem, the more power they’ll create. That’s why the size of the panel matters if you’re trying to calculate how much electricity a panel makes.

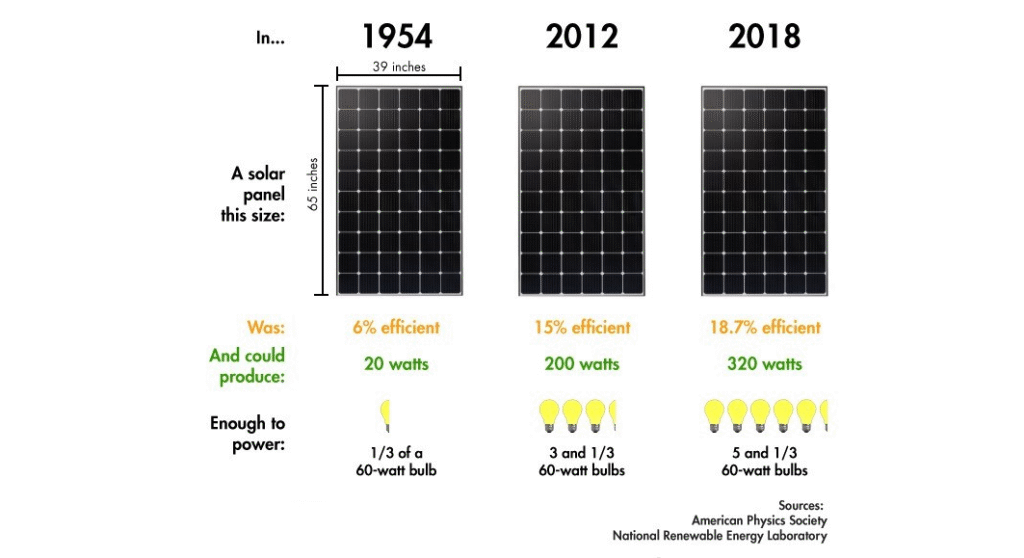

Solar panels have been about this size for decades, but modern panels make more electricity than in the past. That’s because panel manufacturers have found ways to improve cell efficiency over time.

How efficient are solar panels?

Solar efficiency relates to the amount of available energy from the sun that gets converted into electricity.

Back in the 1950s, the first solar cells were capable of taking 6% of the energy from the sun and converting it into electricity.

If they were configured to be the same array of 60 cells you see in the image above, that would have created a current of about 20 watts electricity, about a third of what would be needed to light up a 60 watt incandescent bulb.

When we originally wrote this page in 2012, solar cells could convert 15% of the energy hitting them from the sun into power. As of 2018, the efficiency of the most advanced solar cells is closer to 23%, while average solar cells for residential use are around 18.7% efficient.

If you combine the efficiency of the cells with the size of the panel, you get a number called the “power rating.” In the solar industry, we say “that panel is rated to produce X watts.”

What’s the power rating for an average solar panel?

As of 2018, a typical solar panel produces around 320 watts of power, but panels come in many different wattage ratings, and finding one that produces exactly 320 watts is rare. The top 10 residential solar panels for 2018 includes panels rated to produce anywhere from 290 watts to 360 watts.

More efficient panels are a little more expensive, and are usually only needed if you have limited space on your roof.

Your solar installer will work with you to figure out how many panels you need to produce enough energy for you to use.

It generally matters less how much each panel can produce than how well the whole array performs.

Solar panel output per day and per month

Using the example above of a 250-watt STC rated panel, if you multiply the 250 watts the panel produces by the number of hours of full sun you get in a day, you’ll get the amount of kwh that panel produces per day. Multiply by 30 days and you’ll get mothly kWh output for the panel.

The average roof in the United States gets about 4 hours of usable sun per day. We know the sun shines more than 4 hours, but “full sun” is a measurement that combines all the parts of the day when the sun is lower in the sky into one number.

Using 4 hours of full sun, gives you this equation: 250 watts x 4 hours. That’s 1 kWh (1,000 watts) in a day per 250-watt panel.

If you multiply 1kWh per panel by 30 days in a month, you’ll find that each 250 watt rated panel will produce about 30 kWh in an average month.

How much energy does a solar panel produce per square foot?

The average-sized solar panel takes up an area of 17.6 square feet and produces 265 watts under direct sunlight. That translates to just over 15 watts per square foot.

How many solar panels are needed to power an average house?

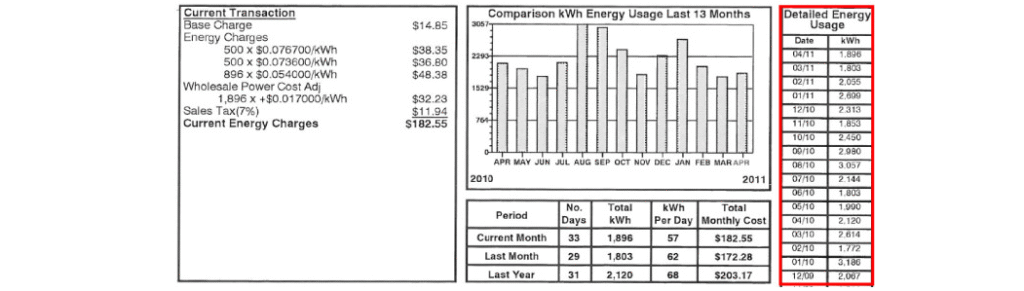

Sizing a solar panel system to your home’s electric usage can be done by taking look at your energy bills over a year.

Most utility companies provide information about your last few months of usage on your bill, but you can probably get more on their website. A few lucky customers get a year and a half like this:

We’ll spare you the trouble of averaging that column, and tell you that this house uses about 2,200 kWh per month. That’s quite a bit higher than the national average, which means the homeowner could really be helped by solar power!

Typically, homeowners in the United States use about 900 kWh a month on average. So, take 900 kWh and divide by the amount of kWh one solar panel produces over the course of a month (30kWh), and you get a 30 panel installation. 30 panels x 250 watts per panel equals a 7,500 watt system (7.5kW).

Again though, these are just rough estimates. It’s best to connect with an expert we trust near you who can appropriately size a system and help take advantage of all the local incentives to get it done right and as affordably as possible.

How much power do my devices use?

There’s huge variation in power use between households depending on what you own and how often you use everything. People in the South and West United States tend to use more electricity for heating and air conditioning, whereas people in the North and East tend to heat with gas or fuel oil.

One basic old-fashioned lightbulb uses 60 watts of electricity; a CFL uses 18 watts. Laptops often use about 45 watts, and desktops can run between 150-300 watts. Window air conditioning can range between 500 and 1500 watts, and central air conditioning can use 3500 watts.

The average home in the US uses about 1,000 kWh of electricity per month. All those little devices add up to big usage, with variations by season. Usage also varies between day and night. Unless you work at home, most of your electricity usage probably happens at night.

On or off the grid?

Since solar panels only generate power as the sun shines, you’ll need a way to store the energy. Though it’s possible to use a battery for storage, the easiest (and cheapest) solution for most people is to stay connected to the grid.

If your solar panels are producing more energy than you’re using—when you’re at work, on vacation, or just not running many devices—excess power will flow back into the grid. In many locations, utility companies offer a program called “net metering” that can compensate you for extra power you produce.

At night, or anytime you need extra power, you’ll pull it from the grid. With a grid-connected system, you’ll never need to worry if you happen to need more power than your solar system has been sized to provide. You may also choose to supply only part of your average electricity bill with solar, and use the grid for the rest.

Your solar installer will talk to you about all of the options. Interested in getting a quote?

Get a Quote!

Share This Post

By

royalstar.trGas Turbine for Power Generation

The use of gas turbines for generating electricity dates back to 1939. Today, gas turbines are one of the most widely-used power generating technologies. Gas turbines are a type of internal combustion (IC) engine in which burning of an air-fuel mixture produces hot gases that spin a turbine to produce power

It is the production of hot gas during fuel combustion, not the fuel itself that the gives gas turbines the name. Gas turbines can utilize a variety of fuels, including natural gas, fuel oils, and synthetic fuels. Combustion occurs continuously in gas turbines, as opposed to reciprocating IC engines, in which combustion occurs intermittently.

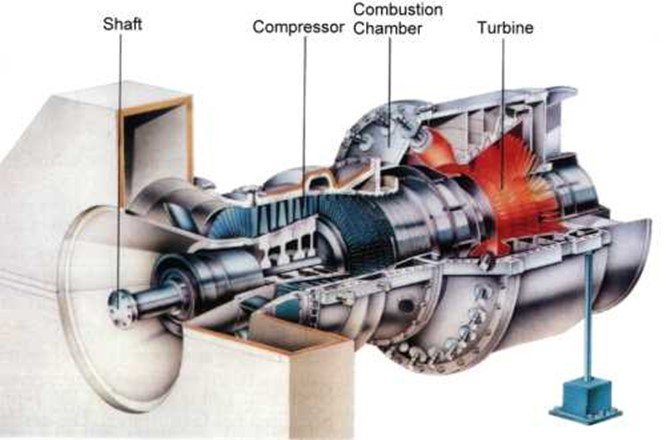

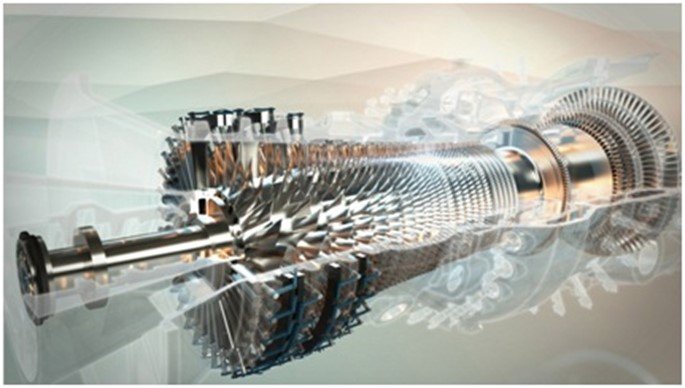

How Do Gas Turbines Work?

Gas turbines are comprised of three primary sections mounted on the same shaft: the compressor, the combustion chamber (or combustor) and the turbine. The compressor can be either axial flow or centrifugal flow. Axial flow compressors are more common in power generation because they have higher flow rates and efficiencies. Axial flow compressors are comprised of multiple stages of rotating and stationary blades (or stators) through which air is drawn in parallel to the axis of rotation and incrementally compressed as it passes through each stage. The acceleration of the air through the rotating blades and diffusion by the stators increases the pressure and reduces the volume of the air. Although no heat is added, the compression of the air also causes the temperature to increase.

The compressed air is mixed with fuel injected through nozzles. The fuel and compressed air can be pre-mixed or the compressed air can be introduced directly into the combustor. The fuel-air mixture ignites under constant pressure conditions and the hot combustion products (gases) are directed through the turbine where it expands rapidly and imparts rotation to the shaft. The turbine is also comprised of stages, each with a row of stationary blades (or nozzles) to direct the expanding gases followed by a row of moving blades. The rotation of the shaft drives the compressor to draw in and compress more air to sustain continuous combustion. The remaining shaft power is used to drive a generator which produces electricity. Approximately 55 to 65 percent of the power produced by the turbine is used to drive the compressor. To optimize the transfer of kinetic energy from the combustion gases to shaft rotation, gas turbines can have multiple compressor and turbine stages.

Because the compressor must reach a certain speed before the combustion process is continuous – or self-sustaining – initial momentum is imparted to the turbine rotor from an external motor, static frequency converter, or the generator itself. The compressor must be smoothly accelerated and reach firing speed before fuel can be introduced and ignition can occur. Turbine speeds vary widely by manufacturer and design, ranging from 2,000 revolutions per minute (rpm) to 10,000 rpm. Initial ignition occurs from one or more spark plugs (depending on combustor design). Once the turbine reaches self-sustaining speed – above 50% of full speed – the power output is enough to drive the compressor, combustion is continuous, and the starter system can be disengaged.

Share this post

By

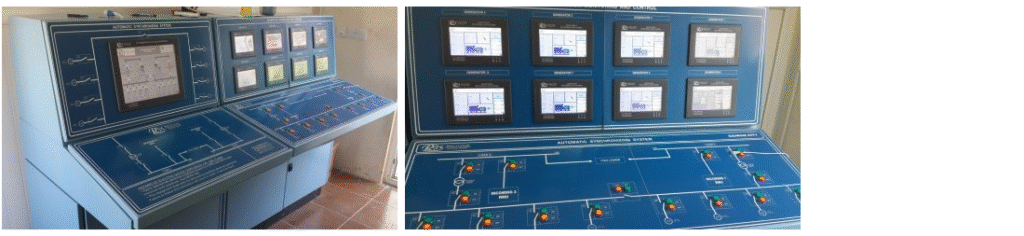

royalstar.trSynchronization Panel

Synchronizing panel will operate on an automatic mains failure system, so that when the main supply is interrupted on one or all phases (after an adjustable delay period) the generator sets will start-up together

After an initial warm-up period (adjustable) the generators will synchronize with each other by means of motorized circuit breakers or contactors onto a common busbar. Next, the motorized change-over switch will be closed and the load will be connected to the main distribution box.

The load share units continuously monitor the load and during low demand periods one or two generators will be shut down to save on fuel consumption. As demand rises again the second generator and third generator will be restarted, synchronized and reconnected to the load. When the AMF control unit detects that the main supply has been restored an adjustable observation period is activated before the main supply is reconnected. A cool down period will then follow, after which the generator sets will be shut down.

Key features of General Control & Synchronization Panel

- 3-pole or 4-pole system as required

- Various combinations of load transfer by ACBs, MCCBs or Contactors

- Protection class up to IP 54

- Load sharing/load shedding

- Automatic and manual synchronizing

- Factory built to client’s specifications

- Ratings up to 6000A

- Control functions available for engine monitoring, warm-up and cool down periods, emergency shutdown, multi attempt engine start control, engine test runs

Share this post